Measuring tools and sensors are essential instruments used across various industries, including construction, manufacturing, engineering, and even home improvement. These tools are designed to provide accurate measurements of dimensions, distances, angles, and other physical properties, making them invaluable for professionals and DIY enthusiasts alike. Whether you are a contractor needing precise measurements for a project or a hobbyist looking to ensure accuracy in your work, selecting the right measuring tools and sensors can significantly impact the quality of your results.

When choosing measuring tools and sensors, several key factors should be considered to ensure you select the best product for your needs. First, consider the type of measurement you need to perform. For instance, laser distance meters are excellent for measuring long distances quickly and accurately, while calipers are ideal for measuring small dimensions with precision. Additionally, think about the range and accuracy of the tool. Some applications may require high precision, while others may be more forgiving. Always check the specifications to ensure the tool meets your requirements.

Another important parameter is the material and build quality of the measuring tool. Tools made from durable materials such as stainless steel or high-quality plastics tend to last longer and withstand wear and tear better than cheaper alternatives. Features such as waterproofing, shock resistance, and ergonomic design can also enhance usability and longevity. For sensors, consider the technology used, such as ultrasonic, infrared, or capacitive, as each has its advantages and limitations depending on the application.

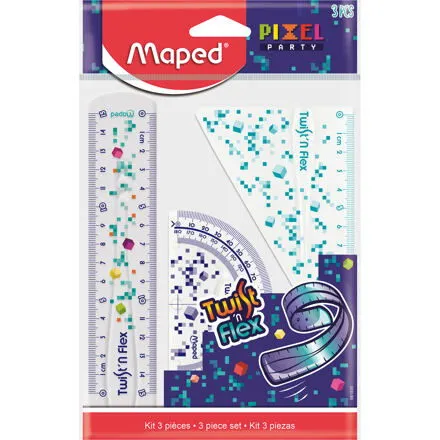

Different variations of measuring tools and sensors come with their own sets of advantages and disadvantages. For example, digital measuring tools often provide quick readings and can store data, making them convenient for repetitive tasks. However, they may require batteries and can be more expensive than their analog counterparts. On the other hand, traditional tools like tape measures and rulers are reliable and do not require power, but they may not offer the same level of precision or ease of use in certain situations.

To get the most out of your measuring tools and sensors, proper usage and maintenance are crucial. Always read the manufacturer’s instructions to understand how to operate the tool correctly. Regularly calibrate your tools to ensure accuracy, especially if they are used frequently or in critical applications. Cleaning your tools after use, especially those that come into contact with dust or moisture, will help maintain their functionality and extend their lifespan.

Additionally, consider combining your measuring tools with other equipment for enhanced efficiency. For instance, using a laser level in conjunction with a laser distance meter can help ensure that your measurements are not only accurate but also aligned correctly. Similarly, pairing a digital caliper with a data logging software can streamline your workflow, especially in a professional setting.

In conclusion, selecting the right measuring tools and sensors involves understanding your specific needs, considering key factors such as accuracy, material quality, and features, and being aware of the advantages and disadvantages of different product variations. By following practical tips for usage and maintenance, and by combining tools effectively, you can enhance your measuring capabilities and achieve better results in your projects. Whether you are a seasoned professional or a novice, investing time in choosing the right measuring tools will pay off in the quality and precision of your work.

show more text